TruePoint provided 3D laser scanning services for John Glenn International Airport in Columbus, Ohio.

Case Study: Laser Scanning Expedites Airport Renovations

Location: Columbus, Ohio

Task: TruePoint provided 3D laser scanning services for John Glenn International Airport (formerly Port Columbus International Airport) in Columbus, Ohio. The client was upgrading the existing airport entrance to add more curb appeal; renovations which included the installation of a prefabricated ceiling panel system and new doors. The primary objective of the laser scan was to capture the ground, curbs, ceiling beams and related structural features to design and prefabricate the upgrades.

Challenge: There were many challenges for this client. The airport needed to remain in operation with little to no interruptions. The client was under a tight timeline, and only had a 60-day window to design and plan for the upgrades at the airport. They discovered the airport entrance was not built exactly to the architectural drawing; most notably that the ceiling structure was sloped where the drawings showed it level. They needed an accurate as-built survey to tie the upgrades to the existing structure and align with the camber of the structure. This would minimize or eliminate any assumptions that could lead to field changes and schedule delays during construction.

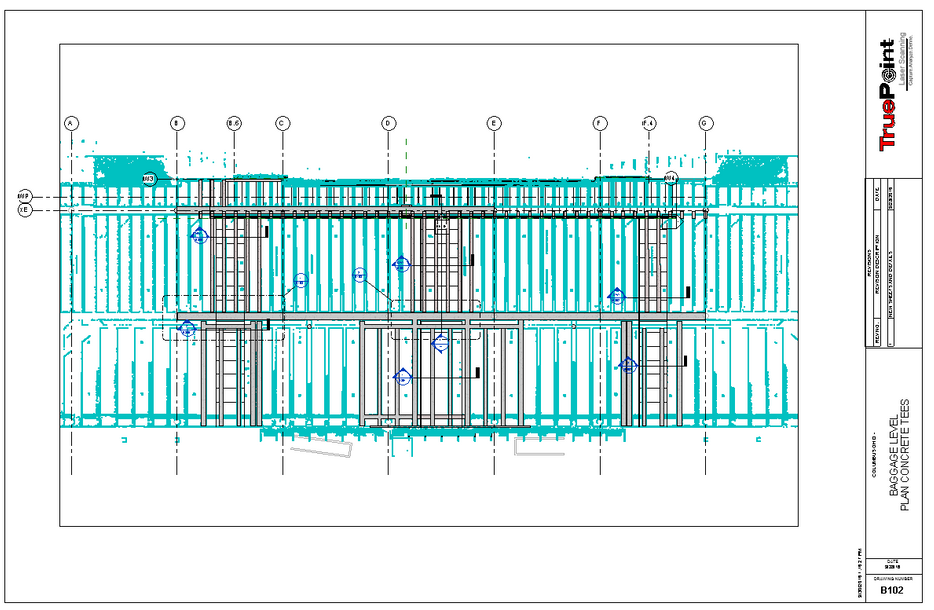

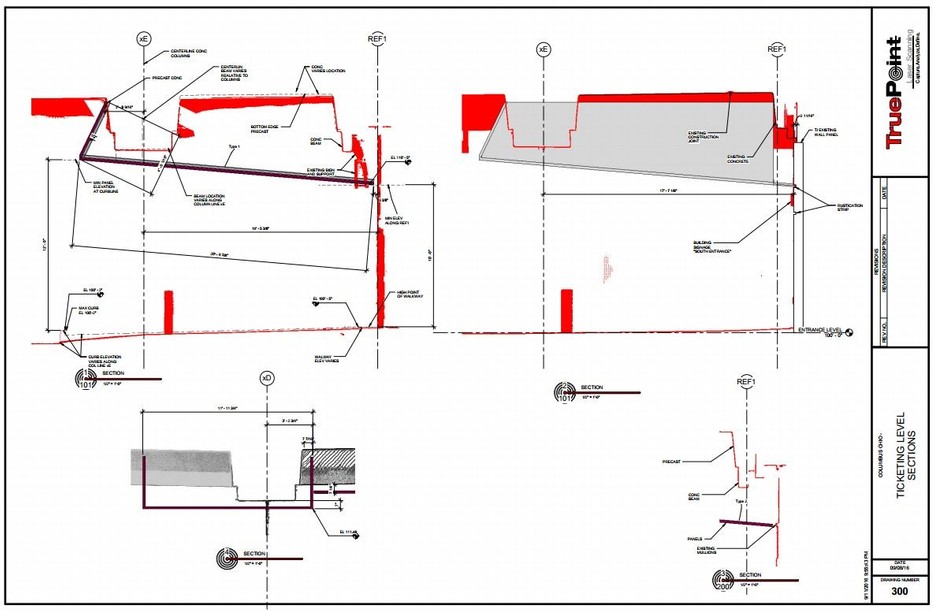

The ceiling panel system was being installed in the airport at two levels, the ticketing and baggage claim. In addition to the camber in the beams, the width and height differed in the two levels. The client had to deliver precise measurements to the prefabricator of the new ceiling panel system. The new doors and entryway were custom-built and these measurements also had to be precise. The client did not have a team of in-house engineers to aid in planning these renovations, that’s where TruePoint Laser Scanning could help.

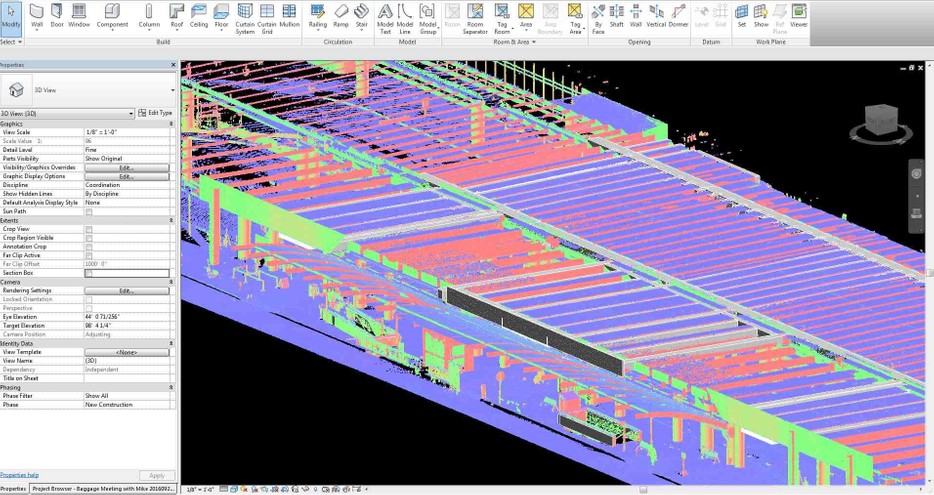

Solutions: The TruePoint Regional Manager worked closely with the client to develop a scope of work and expedite the high definition laser scanning. TruePoint laser scanned the ticketing area in one working day and the baggage claim area in two working days. With nearly 7 million annual passengers, scans were completed during low passenger activity periods, mainly at night.

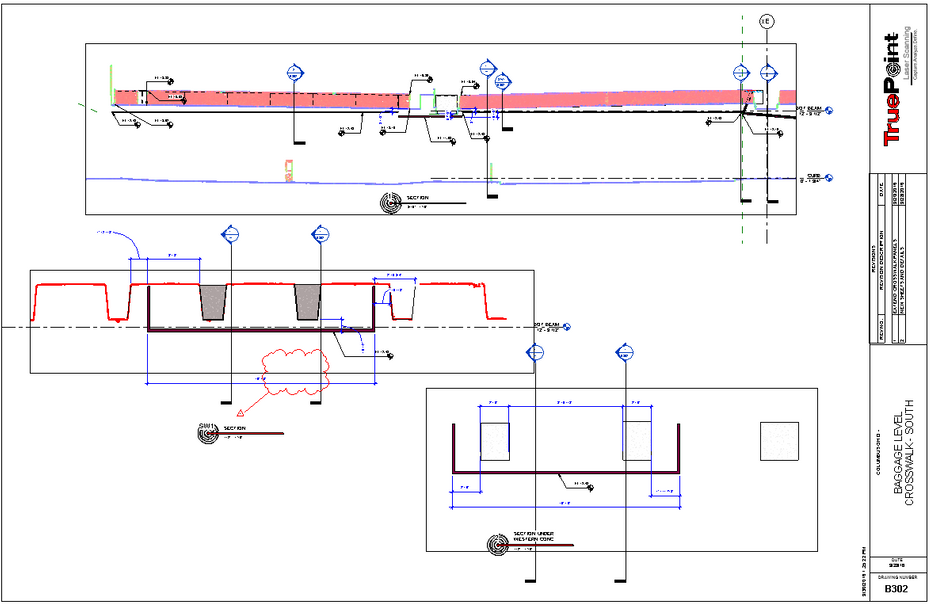

TruePoint architects and engineers worked closely with the client to create drawings for the fabricator to expedite components and minimize inaccuracies. This provided cost savings and eliminated field adjustments and delays during the renovation. The laser scan data also helped the client to plan how the new entrance would tie into the existing entrance taking into account all of the field variables.

Deliverables: The original scope was for engineers at TruePoint Laser Scanning to deliver a 3D model derived from the point cloud data and TruViews, which are 360 degree 3D photographs overlaid on top of the point cloud data. Additional scope was added to create a variety of 2D drawings for the fabricator.

Added Value: The client intended to deliver the point cloud data to the fabricator of the panels. After finding out the fabricator was unsure how to use the data, the client met with TruePoint’s Lead Structural Engineer and Technical Manager in Toledo, OH and realized the value of the laser scan data. TruePoint helped the client determine the ceiling panel dimensions from the point cloud data and provided this information to the fabricator to expedite the ceiling panels. TruePoint’s experienced team of 3D laser scanning professionals, architects and engineers can help you turn any project around quickly, accurately and cost effectively.

If you’re looking for 3D laser scanning services in the Columbus, Ohio area call TruePoint Laser Scanning at 614-800-0378 or email at columbus@truepointscanning.com.

Want to hear more about our different applications? We offer Lunch ’n Learn presentations at your office!

The client was installing a ceiling panel system in the ticketing and baggage claim areas.

TruePoint’s engineers delivered dimensions to prefabricate a ceiling panel system.

Deliverable showing the ticketing level dimensions.

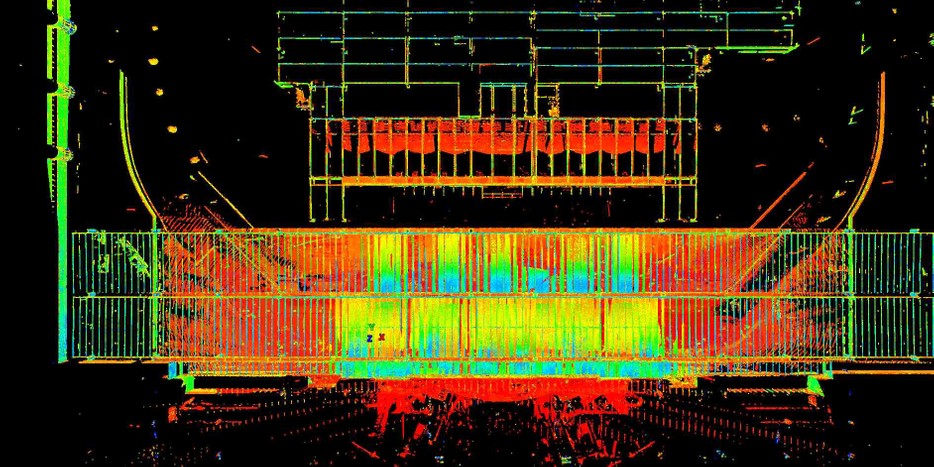

Autodesk Revit software showing a 3D view of the baggage claim area.

TruePoint uses Navisworks software, which allows architects, engineers and construction professionals to review integrated models for clash detection and gain better control over project outcomes.

2D AutoCAD drawing showing the point cloud and fabrication design of the baggage level crosswalk area.

Leica Cyclone screen shot showing the 3D Point Cloud data of the ticketing area.