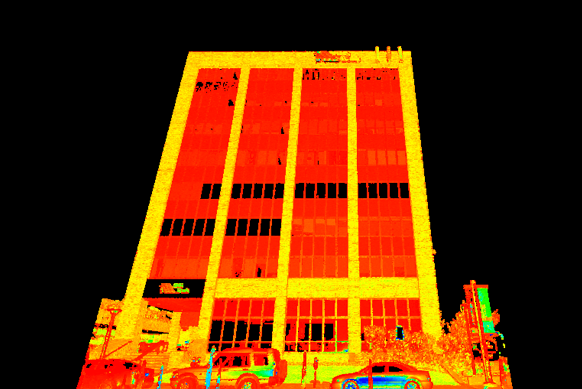

Colorized point cloud of building exterior to replace building envelope system and panels.

Case Study: Laser Scanning Existing Building to Install Aluminum Composite Panels

Location: Denver, Colorado

Task: TruePoint Laser Scanning was requested to 3D laser scan an existing bank and office building. This client needed precise measurements of the building facade for the fabrication and installation of aluminum composite panels. The point cloud and 3D model needed to be within ¼ inch accuracy in order for the paneling to properly fit.

Challenge: This site was an active bank and office building. Laser scanning needed to be accomplished in a quick and efficient way with no impact on the tenant or its clients. Another challenge was capturing the entirety of the exterior. This building was eight stories tall with one floor that was below grade. TruePoint was able to utilize the 120-300 meter range of their laser scanners to complete scans from walkways, sidewalks, and adjacent properties. Data was quickly taken from ground level without scaffolding or lifts.

Solution: TruePoint quickly responded to the client’s needs and scanned the exterior of the building in just one day. Measurements done without laser scanning would have been cost-intensive. Through the use of laser scanning, TruePoint collected comprehensive information saving the client both time and money. The accuracy of measurement also saved cost on the fabrication of the aluminum composite panels.

Deliverables: The requested deliverable from the client was a colorized point cloud. In order to provide a colorized point cloud, the scanner completed a full scan and took 260 pictures that are stitched over the point cloud. Our on-staff architects and engineers worked with this first time client to make sure they could utilize the point cloud in the most efficient, effective manner for this application.

Added Value: When accuracy matters TruePoint will deliver! TruePoint utilizes survey grade laser scanners for all of their projects to ensure the highest quality and accuracy possible. The alternative to laser scanning would have been taking hundreds of measurements with a standard tape measure. With the scan areas being difficult to access and tough to maneuver, it could have taken days or even weeks to manually measure the areas. TruePoint also eliminated the need for lifts or scaffolding, which could have impeded operations in this active building and added additional time and cost to the client.

If you are in the Denver area and are in need of as-builts, construction verification, or architectural documentation call or email TruePoint’s Mountain Region office for a quote! Contact Dave Schaff at 720-618-1029 or denver@truepointscanning.com

Interested and want to hear more? We offer Lunch ‘n Learn presentations at your office!

Intensity map point cloud of building facade.