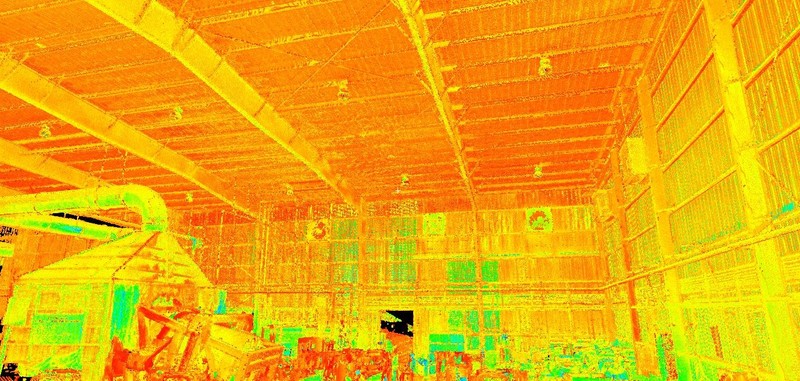

Intensity Map Point Cloud showing the building's interior structure

Case Study: Laser Scanning Serves to Create As-Builts for Possible Plant Expansion

Location: Bowling Green, Kentucky

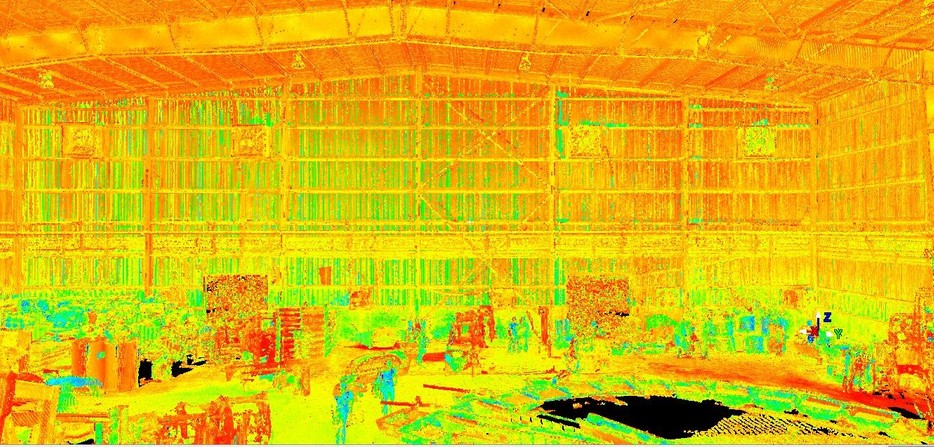

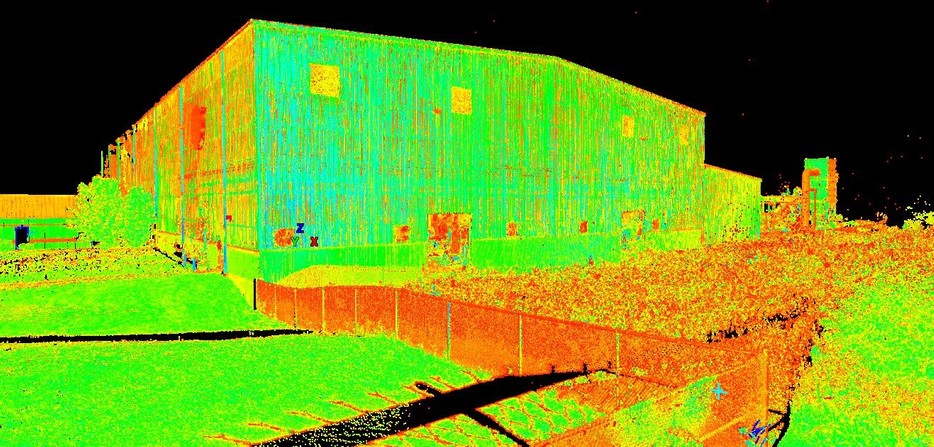

Task: To accurately capture the as-built conditions of the interior and exterior of the building. The focus of the scan was on capturing the basic interior and exterior structural features of the building, including wall surfaces, cross bracing, portal openings, floors, and ceiling. The other goal of the scan, though, was also to capture the exterior 50 to 100 foot perimeter around the building's structure. The facility was looking to add additional machinery, and our client was responsible for finding out if the current structure was sufficient or if an addition would be needed to accommodate the new equipment.

Challenge: Our client needed to obtain accurate measurements of the space in question without stopping production or occupying the product storage areas of the facility with ladders, lifts, or scaffolding, the kind of equipment which would have been needed to obtain the measurements in the traditional manner.

Solutions: With laser scanning, technicians can capture data accurately from a distance, so the technology can be used safely from ground level. In this way, TruePoint was able to place the scanner at non-obtrusive locations and capture the data even while the plant was in full production. Additionally, by placing the scanner in several different locations, TruePoint was able to capture the necessary data from various angles, providing a full dimensional “picture” of the focus area.

Deliverable: The client was provided with the raw point cloud data (.pcg file format), which he then was able to import directly into his AutoCAD software. From the point cloud data, he was able to obtain the dimensions needed to complete his layout and designs.

Added Value: By scanning the existing equipment while also capturing the as-is conditions of the structure, TruePoint was able to provide the client with dimensional information about the equipment, information which the client used to lay out the proposed new floor plan, showing how the equipment would fit and assessing how much space was necessary to avoid potential clashes.

Also, by using the door openings of the building to place targets, TruePoint was able to tie the interior and exterior scan data from the building and surrounding topography together in a single point cloud. By having the interior and exterior data tied together, it is now possible to determine where to put penetrations, as well as see exactly where the penetrations will come through on both sides.

If you have an existing project that requires accurate as-builts for renovations, contact TruePoint Laser Scanning today at 513-609-7244 or cincinnati@truepointscanning.com to discuss your project.

Raw point cloud showing facility in operation

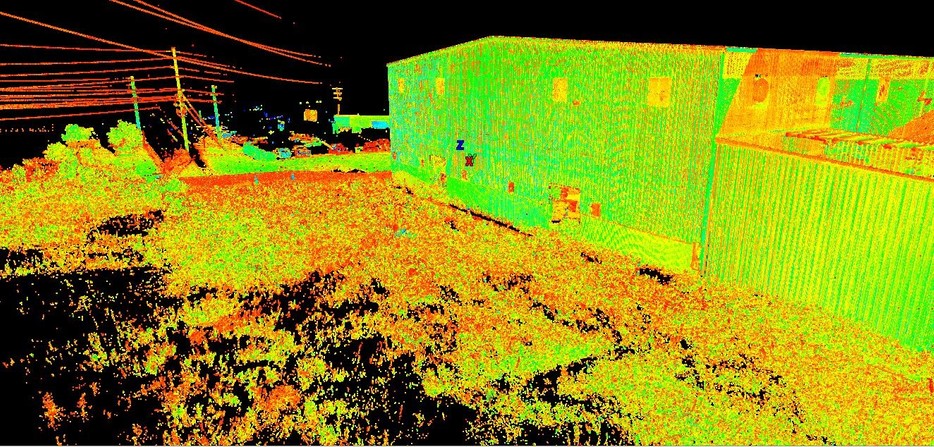

Point Cloud of building structure and surrounding area

Intensity Map capturing ground to overhead clearances and building structure