What is a Digital Twin?

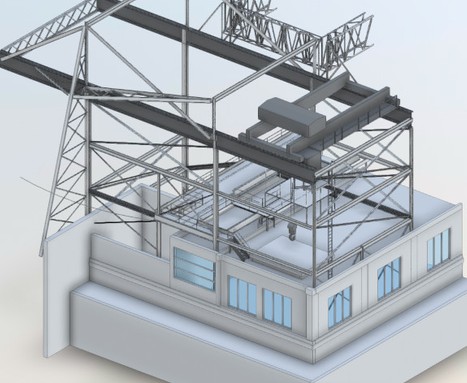

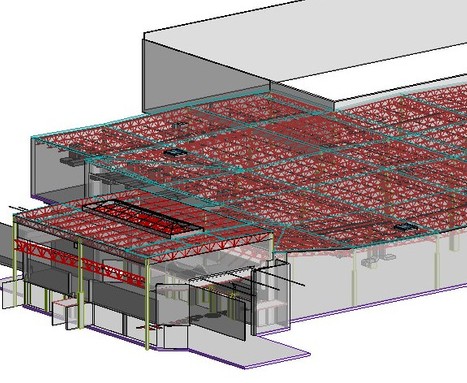

A digital twin is a virtual model that accurately represents an existing physical space. It digitally represents a building’s architecture, structure and systems. The most useful purpose of digital twin technology occurs during the construction design and planning process. A digital twin can be used to plan for building improvements, improve efficiencies and optimize workflows, which can then be applied back to the actual physical asset. In a digital twin environment, ideas can be tested with few limitations. A digital twin can also be an important post-construction process as it connects the design to the management of a building.

How do you create a digital twin?

1. Define the Project Scope

The first step to creating a digital twin is defining the project scope. What exact details of the space do you want to capture? Provide a clear description of the project scope. This will ensure all necessary project information is collected while onsite the first time.

2. Determine Data Collection Tools

Digital twin data collection is implemented by any number of 3D laser scanning systems. TruePoint uses industry-leading Leica laser scanners to collect up to 2 million measurement points per second with 2-4 mm accuracy at a range of up to 270 meters for each scan taken.

3. Select a Software

To carry out the digital twin, selecting a technology or software is necessary. Choosing the right software is essential. For example, a digital twin model can be constructed in Revit, AutoCAD, ReCap, Navisworks, Civil 3D or BIM 360 with the millions of sub-centimeter data points collected. The model will typically be created natively in whatever software is being used by the end user and most software packages are not interchangeable, so if it’s modeled in one software not all features may be available or work in a different software.

What are the benefits of digital twins?

Adopting digital twin technologies can help a company improve workflows, improve collaboration and communication between employees and eliminate time consuming manual tasks.

For design planning, a virtual model enables the integration of financial data in terms of materials and labor costs. With a large amount of real-time data and analytics, businesses make better and faster decisions.

For physical systems, a digital twin offers a real-time and in-depth view of the existing conditions. It can be accessed anywhere, enabling users to monitor the system’s performance remotely. It can help identify the issues within a system, enabling engineers to accurately schedule predictive maintenance, resulting in lower maintenance costs.

Ultimately digital twins can help companies operate more efficiently, cut costs and remain competitive. The McKinsey Global Institute reports that a digital transformation can increase productivity by up to 15% and reduce costs by up to 6%. Digital twins can help construction firms offset high material costs and shrinking budgets.

Does TruePoint offer digital twin services?

Yes. TruePoint is a leading 3D laser scanning and scan to BIM service provider. We are experts in design planning and construction technologies, offering digital twin services to architectural, engineering, and construction professionals. We help clients leverage the latest advancements in construction technology to improve project planning.